iWorld First – Scientists Convert Heat into Electricity Using Tungsten Disilicide, researchers have achieved a significant milestone by successfully converting heat into electricity using tungsten disilicide, marking a new chapter in energy science. This development, which stands at the intersection of material science and energy sustainability, showcases how heat—a previously underutilized resource—can be transformed into a viable source of electricity. Tungsten disilicide, a material previously known for its high-temperature resilience, has been repurposed to harness the energy that exists in waste heat, turning it into electrical power with remarkable efficiency.

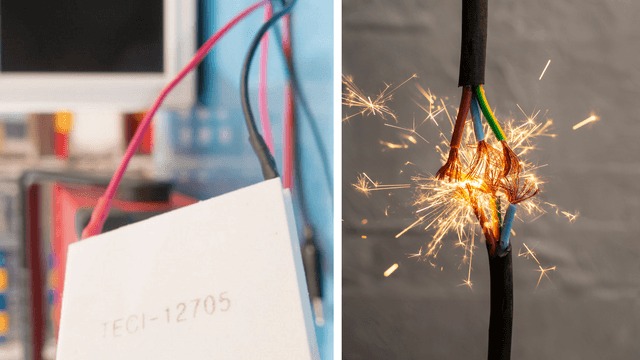

This innovation revolves around the unique properties of tungsten disilicide, a compound recognized for its thermal and electrical conductivity. The material operates on thermoelectric principles, which involve the direct conversion of temperature gradients into electrical voltage. The breakthrough here lies not just in the application of tungsten disilicide but also in how it addresses long-standing challenges in the thermoelectric field, such as inefficiency and cost. With this technology, you may soon witness a more sustainable approach to energy usage, particularly in industrial processes and systems that generate vast amounts of waste heat.

To comprehend the significance of this achievement, you must first appreciate the concept of thermoelectric conversion. Thermoelectric materials generate electricity by exploiting temperature differences. When one side of the material is heated while the other remains cool, a voltage difference arises due to the movement of charge carriers. Tungsten disilicide enhances this process, offering a high Seebeck coefficient—a measure of its ability to convert temperature differences into electrical voltage—combined with excellent electrical conductivity. This rare combination makes it an ideal candidate for efficient energy conversion.

The journey to this breakthrough was neither straightforward nor rapid. Scientists faced numerous hurdles, including the material’s high production cost and the difficulty of achieving scalable results. Tungsten disilicide’s natural properties required refinement and optimization to reach the levels of performance observed in recent experiments. By employing advanced manufacturing techniques and leveraging nanoscale engineering, researchers have overcome these challenges, producing a material that could potentially redefine thermoelectric applications.

The implications of this innovation extend far beyond the laboratory. In industrial settings, waste heat is often an inevitable byproduct of manufacturing, power generation, and transportation. Currently, much of this heat is dissipated into the environment, contributing to energy loss and environmental degradation. With tungsten disilicide-based thermoelectric converters, industries could reclaim this heat and transform it into a sustainable energy source, significantly improving energy efficiency. This is particularly important in energy-intensive sectors such as steel production, where waste heat recovery could lead to substantial cost savings and emissions reductions.

To illustrate the impact of this technology, consider its potential applications across various sectors. For instance, in the automotive industry, engines and exhaust systems produce vast amounts of heat that currently serve no functional purpose. By integrating tungsten disilicide-based converters, vehicles could harness this heat to power electrical systems, reducing reliance on traditional fuel and improving overall efficiency. Similarly, in power plants, waste heat from turbines and generators could be captured and repurposed, enhancing the plant’s output without additional fuel consumption.

| Sector | Waste Heat Source | Potential Application | Impact |

|---|---|---|---|

| Automotive | Engine exhaust | Supplementing electrical systems | Reduced fuel consumption and emissions |

| Industrial | High-temperature manufacturing | Powering auxiliary equipment or feeding the grid | Improved efficiency and cost savings |

| Power Generation | Turbine systems | Enhancing power output | Reduced energy loss |

This development also holds promise for addressing global energy challenges. As the demand for sustainable energy solutions grows, the ability to convert waste heat into electricity offers a dual benefit: reducing energy waste and lowering carbon emissions. It complements renewable energy technologies such as solar and wind, providing a steady energy source that is not dependent on environmental conditions. Additionally, it aligns with international efforts to transition towards greener energy systems and achieve carbon neutrality.

From a technological perspective, the discovery signifies a leap in material science. Tungsten disilicide’s application exemplifies how innovative approaches can unlock the potential of materials that were previously underutilized in energy technologies. This success may inspire further research into similar compounds and hybrid materials, potentially opening new avenues for thermoelectric applications and beyond.

Looking ahead, the next steps involve scaling this technology for real-world applications. While laboratory results are promising, transitioning from experimental setups to commercial products requires overcoming several challenges. These include reducing production costs, enhancing the durability of the material under varying conditions, and developing systems that seamlessly integrate tungsten disilicide converters into existing infrastructure. Addressing these issues will be critical to ensuring the technology’s adoption and success in diverse environments.

The successful conversion of heat into electricity using tungsten disilicide represents a monumental achievement with wide-ranging implications. This innovation not only showcases the ingenuity of modern science but also highlights the potential for sustainable energy solutions to reshape industries and reduce environmental impact. As research progresses, you may witness this technology becoming a cornerstone of energy efficiency initiatives, unlocking new possibilities for a cleaner and more sustainable future.

Add Comment